Home News Company News The Savior of the Filled Masterbatch Ind…

German powder modification technology has always been the top choice in the minds of many professionals in the powder industry. When it comes to German modification technology, industry insiders unanimously give a thumbs up. However, the powder modification process that has troubled most manufacturers in the Chinese domestic rubber and plastic industry, especially in the masterbatch sector, is not the work of foreign companies. Instead, it was pioneered by a Chinese company called Tungkula Particle Machinery Equipment Co., Ltd.

For years, the Chinese masterbatch industry has faced an awkward situation. On one hand, directly purchasing the crucial filler for masterbatch - activated heavy calcium powder - is expensive, leading to high production costs. On the other hand, if they purchase ordinary heavy calcium powder and modify it themselves, suitable equipment is hard to find in the market. Imported equipment comes with prices in the millions, leaving masterbatch industry companies only able to sigh in frustration. Domestic equipment also requires high amounts of modification agents. Taking stearic acid, a commonly used modification agent, as an example, domestic equipment might require anywhere from 5% to 20% stearic acid. With stearic acid's market price at 12,000 RMB per ton, the daily cost becomes substantial over time.

In this context,Tungkula Particle Machinery Equipment Co., Ltd.introduced the T-Mix surface coating modification machine. The Tungkula T-MIX series offers various physical modification processes suitable for different materials, such as disc grinding modification, fluidized bed modification, high-shear mixing modification, and more. The surface coating modification equipment adopts a full-process thermal circulation system and is complemented by a specially designed modification agent addition process. This results in a nearly 100% powder modification rate and modification agent addition amounts that are only 1/5 of those used by other domestic and international manufacturers. Taking calcium oxide as an example, while customers usually modify using 20%, Tungkula can achieve 2.5%-5%. With a modification rate of 99.9% for calcium carbonate and a modification agent usage of less than 1%, perfect modification is achieved.

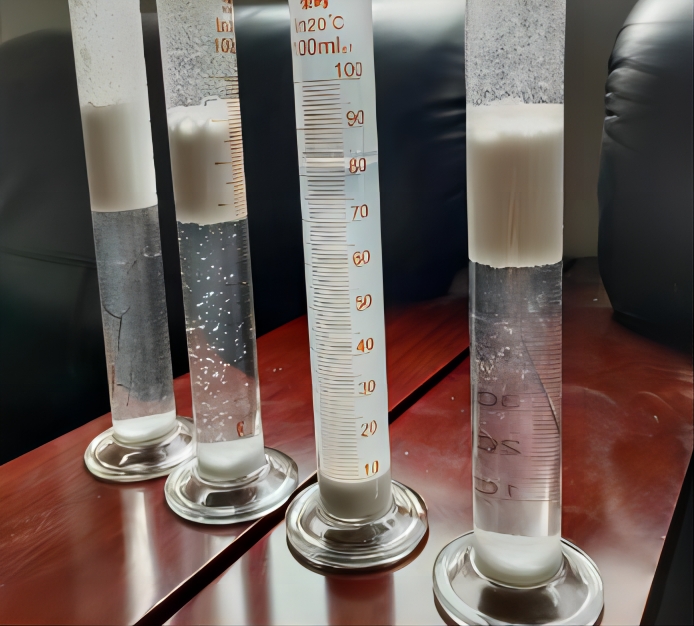

Left side shows the heavy calcium modification effect of a tens of millions-imported equipment, while the right side shows the modification effect of Tungkula T-mix.

This is already at the forefront of global modification efficiency, on par with German and Japanese powder modification technologies. What's even more astonishing is that while German powder modification production lines typically come with million- or even ten-million-dollar price tags, the Tungkula T-Mix modification system is far more affordable than its Western counterparts. This way, the long-standing issue of production costs that have plagued industries like rubber and plastics in China has finally found a comprehensive solution.

As China's industries upgrade, its powder technology is gradually on the rise.

Name: Joye

Mobile:+86 166 2114 0018

Tel:+86 166 2114 0018

Whatsapp:+86 166 2114 0018

Email:info@tungkula.net

Add:Warehouse 3, No.1537, Airport Fourth Road, Xihanggang Economic Development Zone, Shuangliu District, Chengdu, Sichuan Province, China