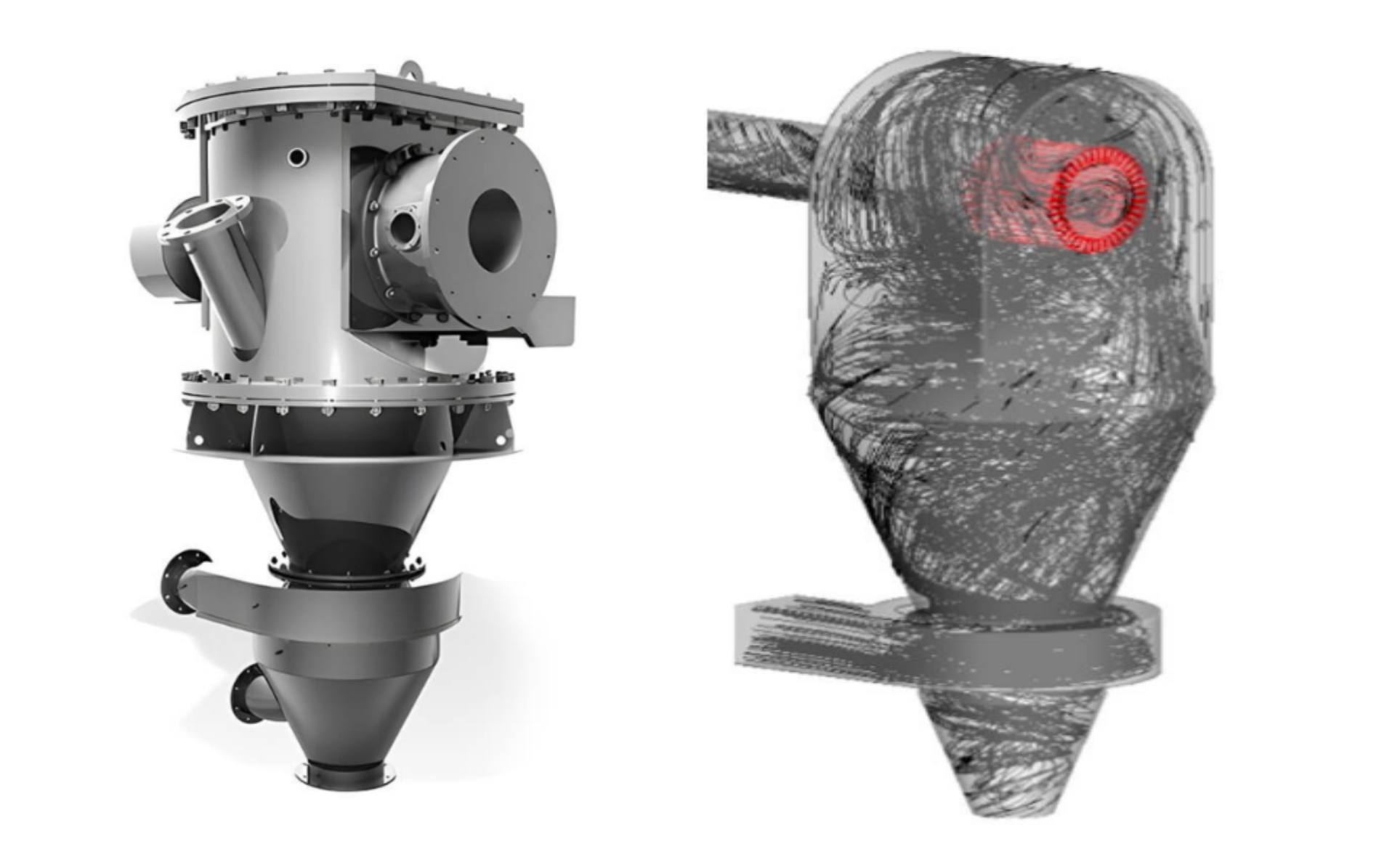

Product Description:

Principle of Operation:

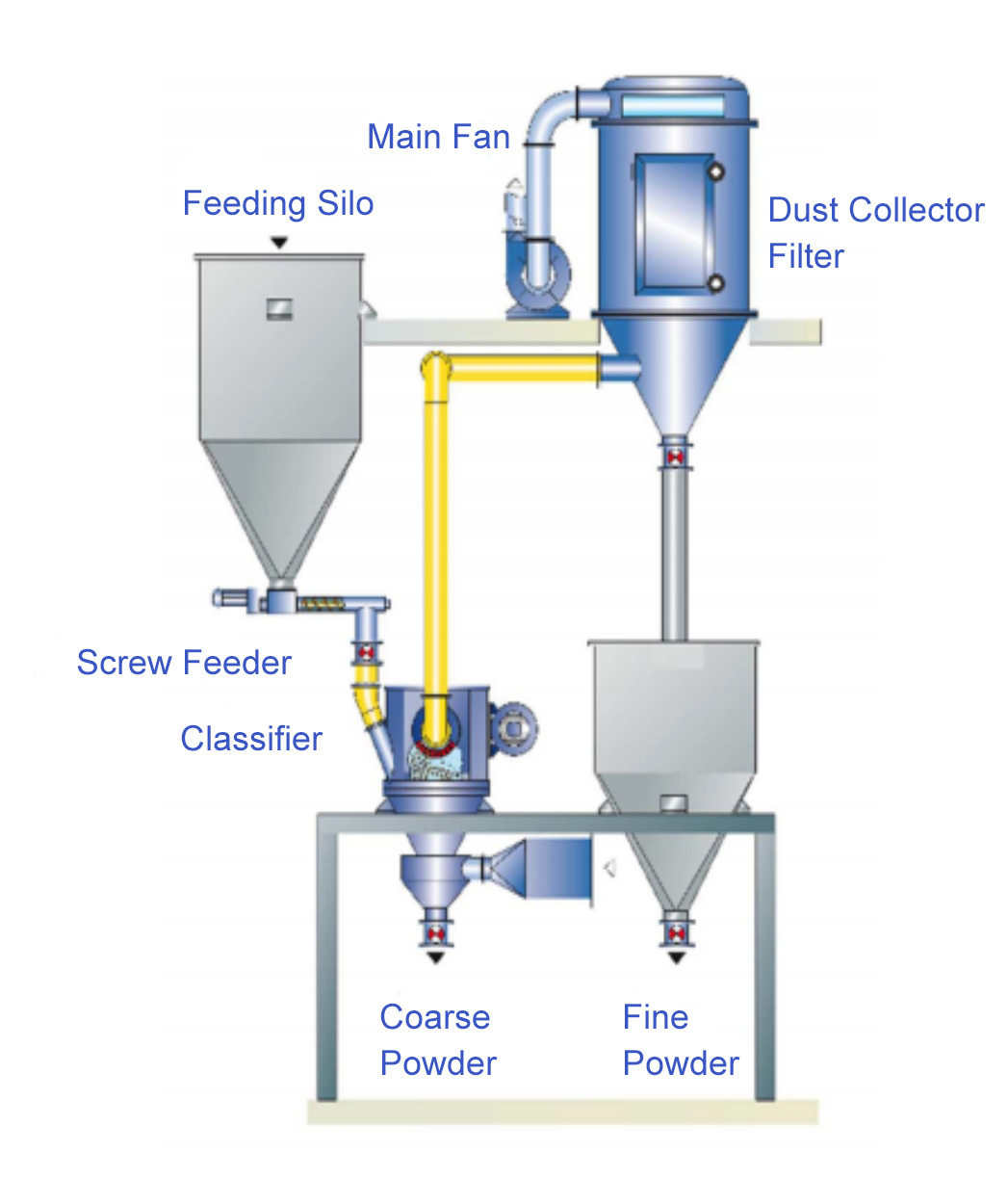

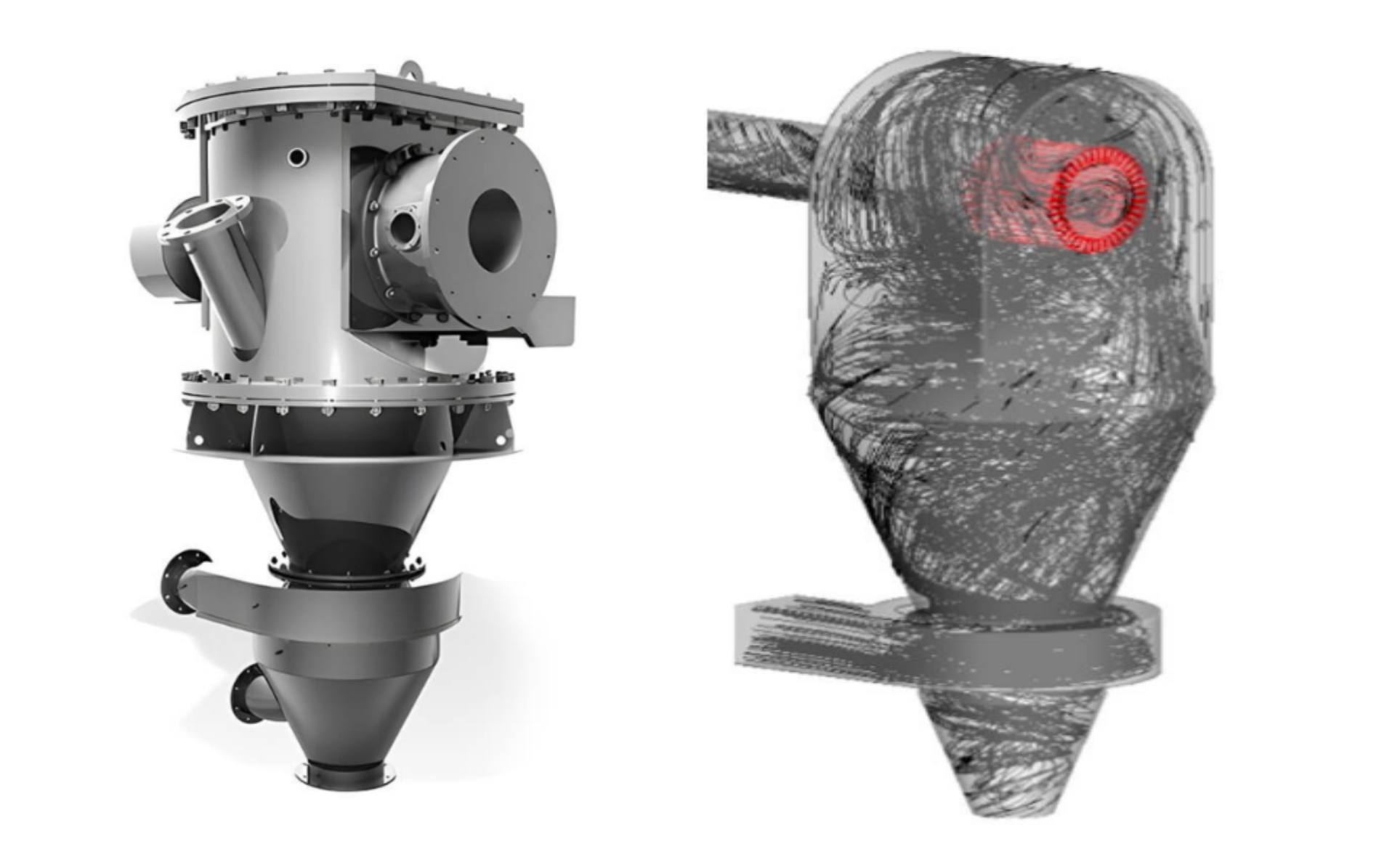

The material to be classified is drawn into the classification chamber by a high negative pressure suction system through a feeding unit. Near the classification wheel, it is subjected to a powerful centrifugal force field. The required fine powder passes through the classification impeller and is then collected by the collection device, while the coarse material falls into the lower part of the classifier. Here, due to the influence of secondary air intake, it is dispersed again, and the fine powder mixed in the coarse powder re-enters the classification zone with the airflow, while the coarse material falls along the inner wall to be collected. The classification impeller and the chamber wall are equipped with an airflow sealing mechanism, ensuring superior sealing effect and more uniform discharge particle size. Optimal classification results can be achieved by precisely adjusting the speed of the classification wheel motor and the magnitude of the secondary air intake.

Performance Features:

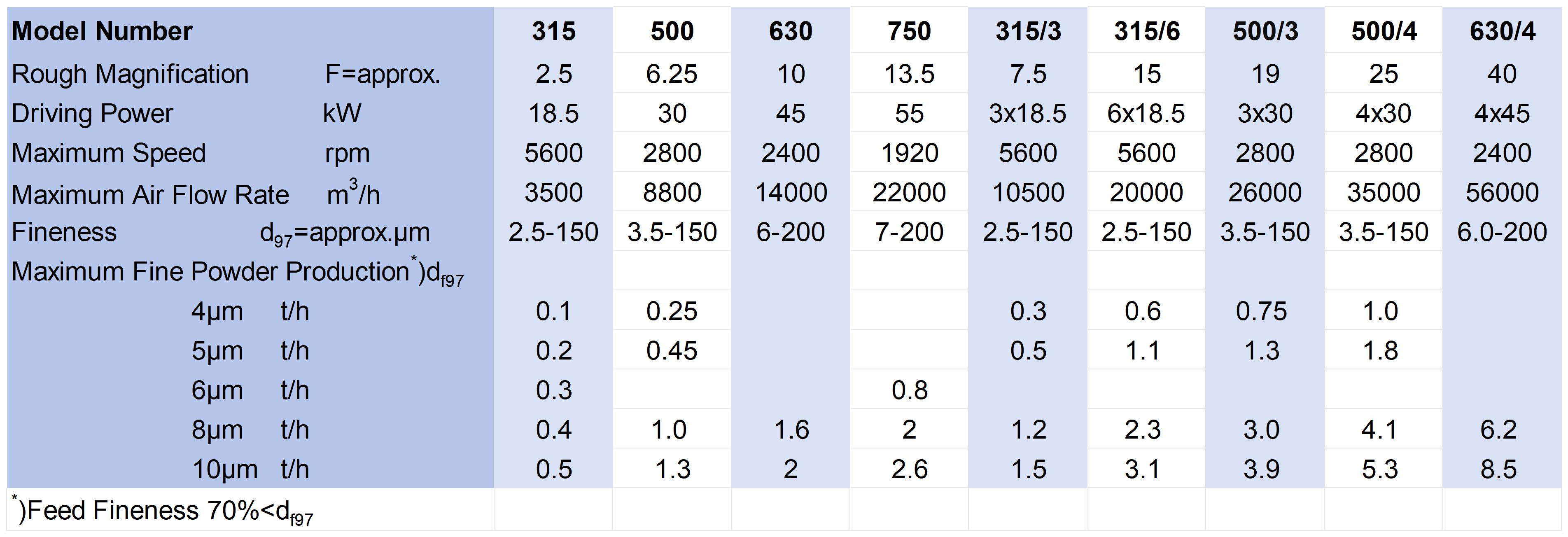

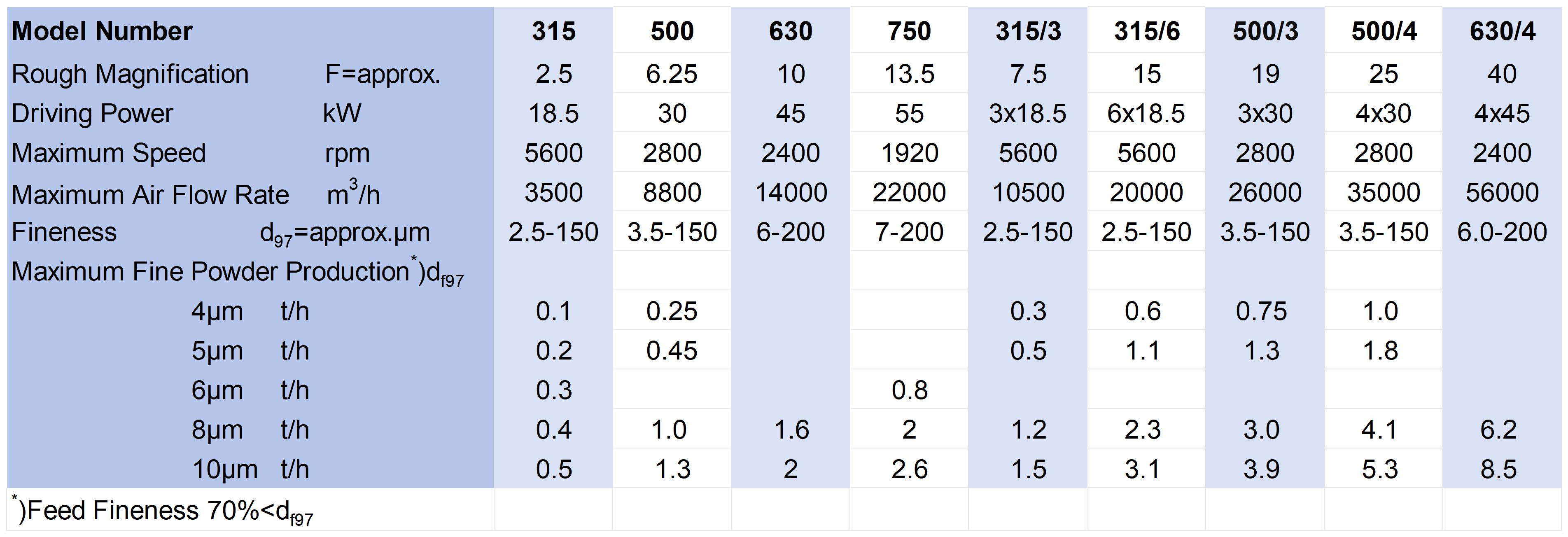

1. Adopts the principle of turbo classification, with secondary air intake and stepless speed regulation of the classification turbine. Equipped with an airflow sealing device, the classification accuracy is high, and the classification range is wide, allowing adjustment of the finished particle size between 3 and 150 microns. Depending on the characteristics of different materials, the classification range varies from D50: 0.6 to 50 microns.

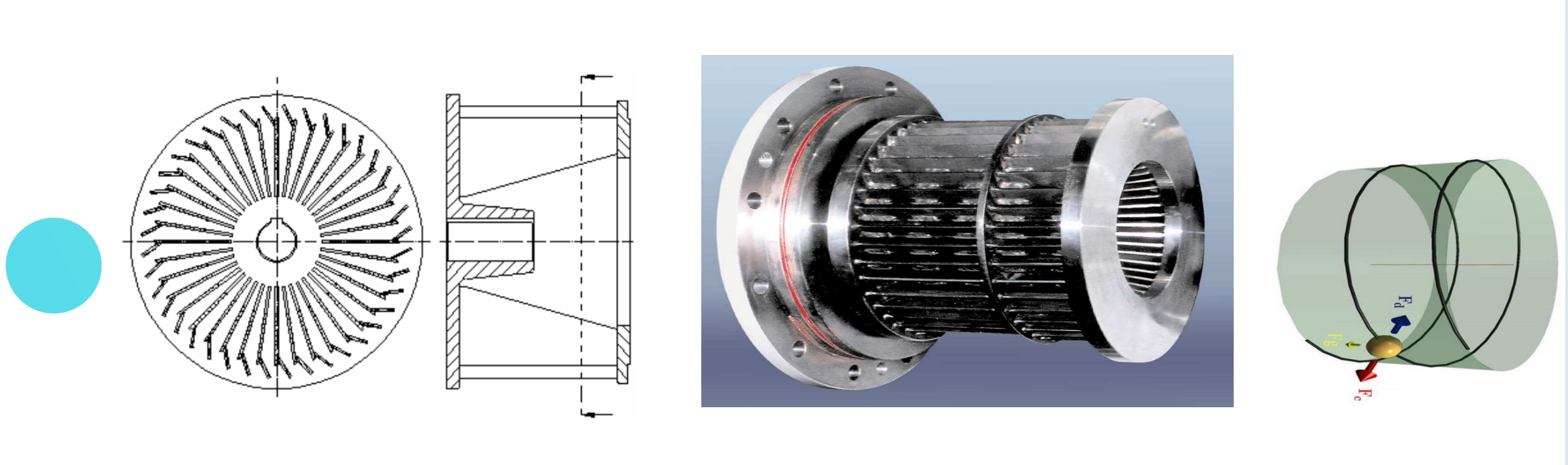

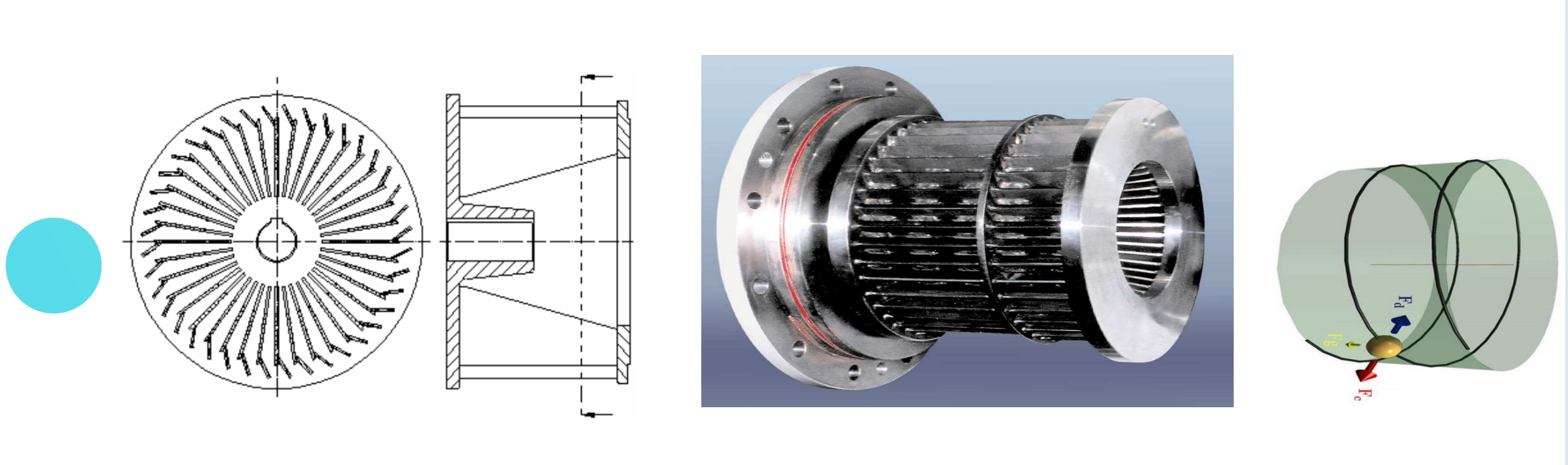

2. The blades of the classification impeller are made of special high-strength wear-resistant materials, greatly improving the stability of high-speed operation and extending the service life. When processing sticky and cohesive materials, it significantly reduces the deposition of fine powder in the discharge pipe.

3. Adjustable product particle size, precise cut-off point, steep particle size distribution, suitable for various spherical, flake, and needle-shaped particles.

Horizontal classification wheel provides better particle size cutting efficiency, lower pressure drop, and reduced energy consumption. Additionally, the horizontal vortex formed offers better control over large particles.

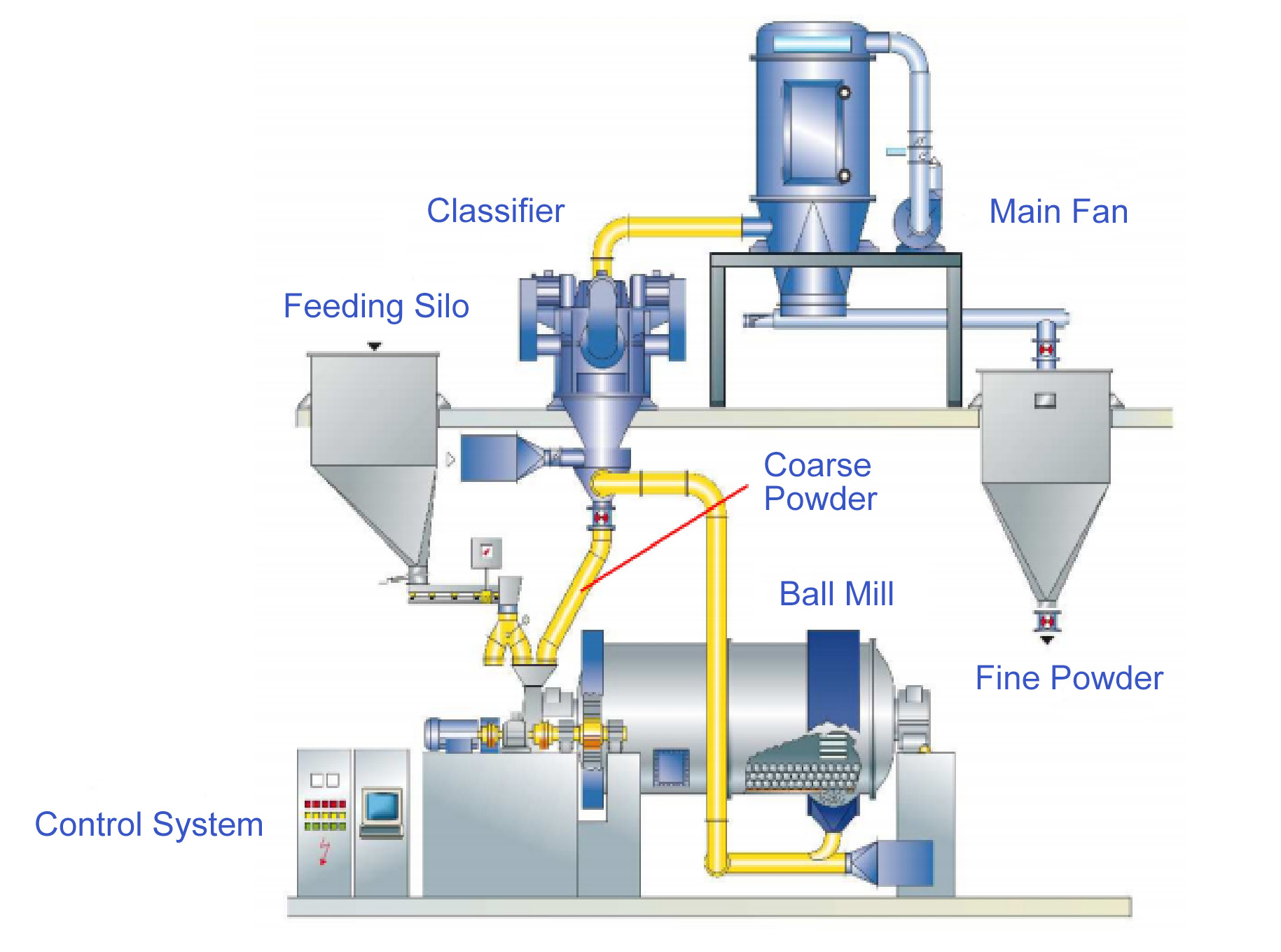

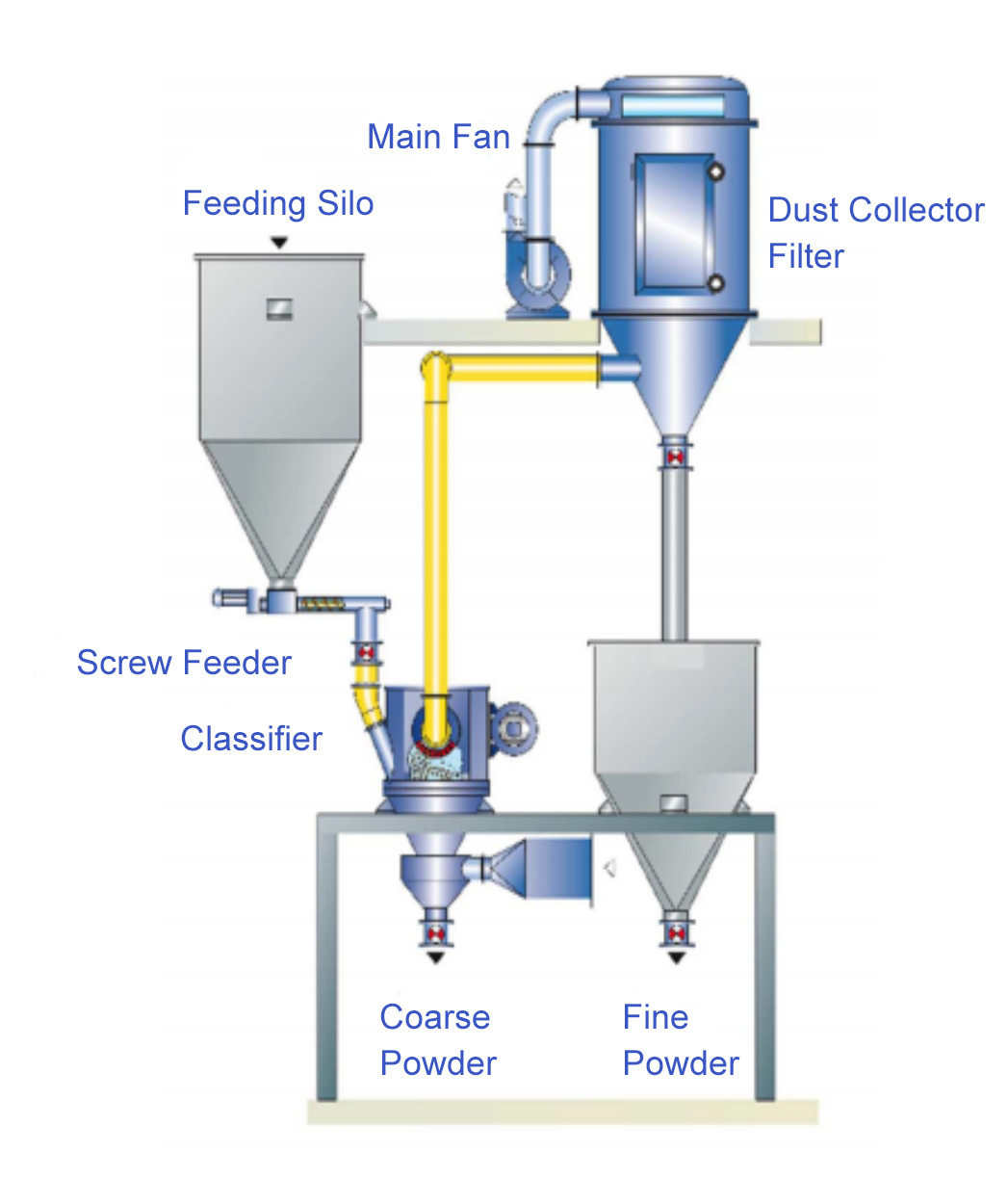

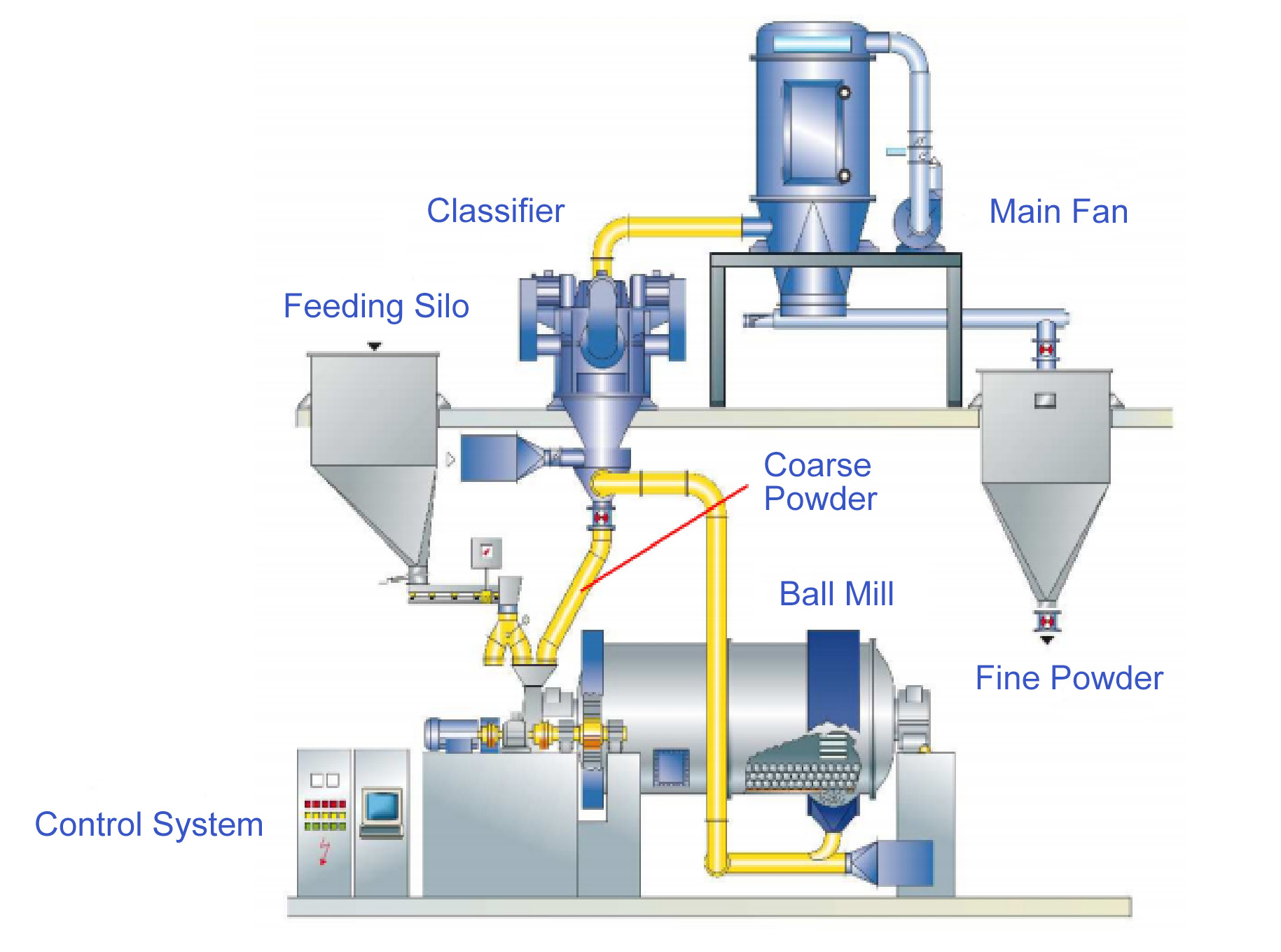

TAC Process Flow

Application:

Energy, Chemical, Pharmaceutical, Cosmetics

Metal powder, Ceramic powder, Alloy powder, Battery materials,

Limestone, Marble, Talcum powder, Silicon powder, Graphite, Barite,

Mica, Kaolin

Product features:

Horizontal installation of grading wheel reduces height difference, facilitating uniform particle distribution.

Ultimate PID dynamic balance reduces the passage of large particles.

Multiple circulation of incoming air ensures thorough dispersion even with fluctuating feed.

Stable operation even with fluctuating feed rates.

Wide application.

High-precision scientific and technological technology.

User-friendly design, easy replacement of grading wheel.

Low maintenance cost.