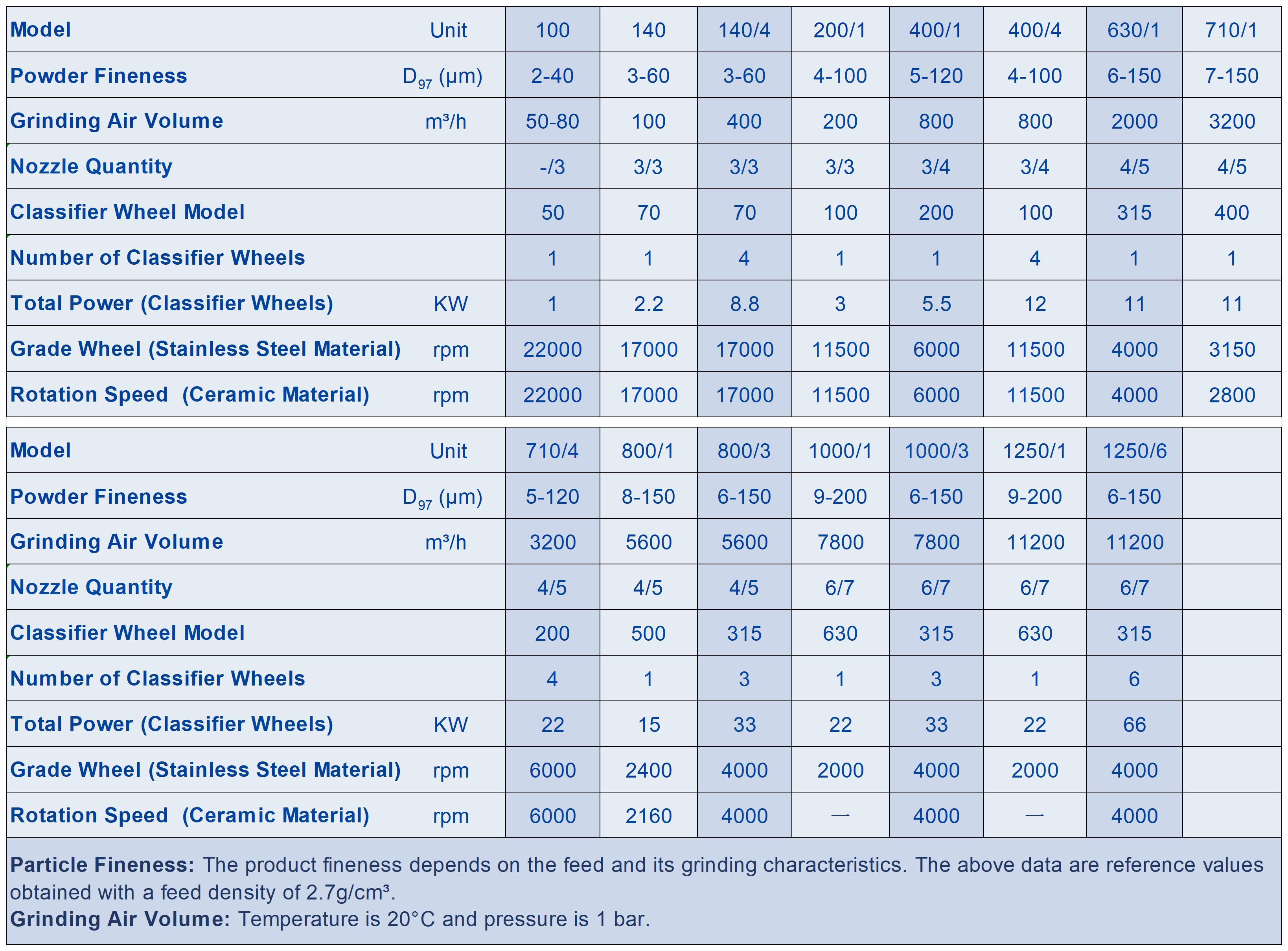

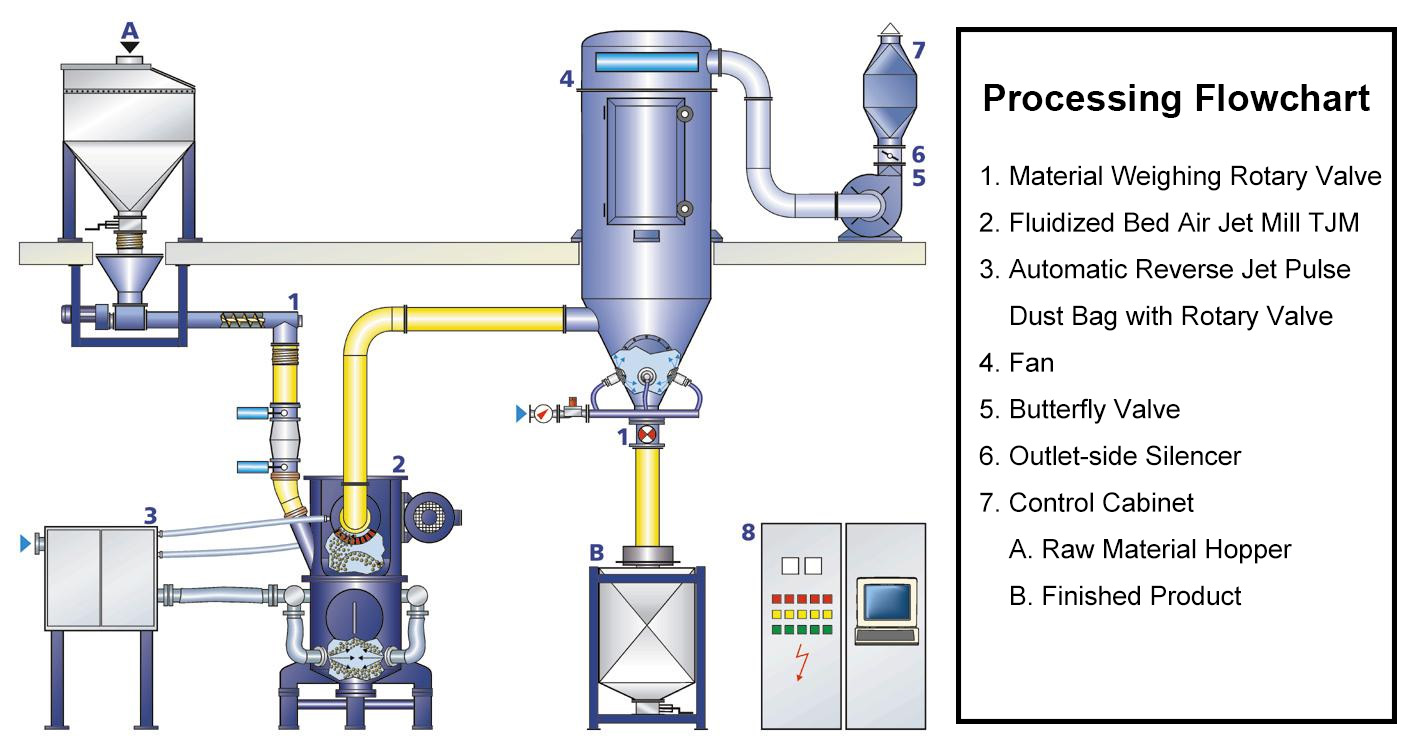

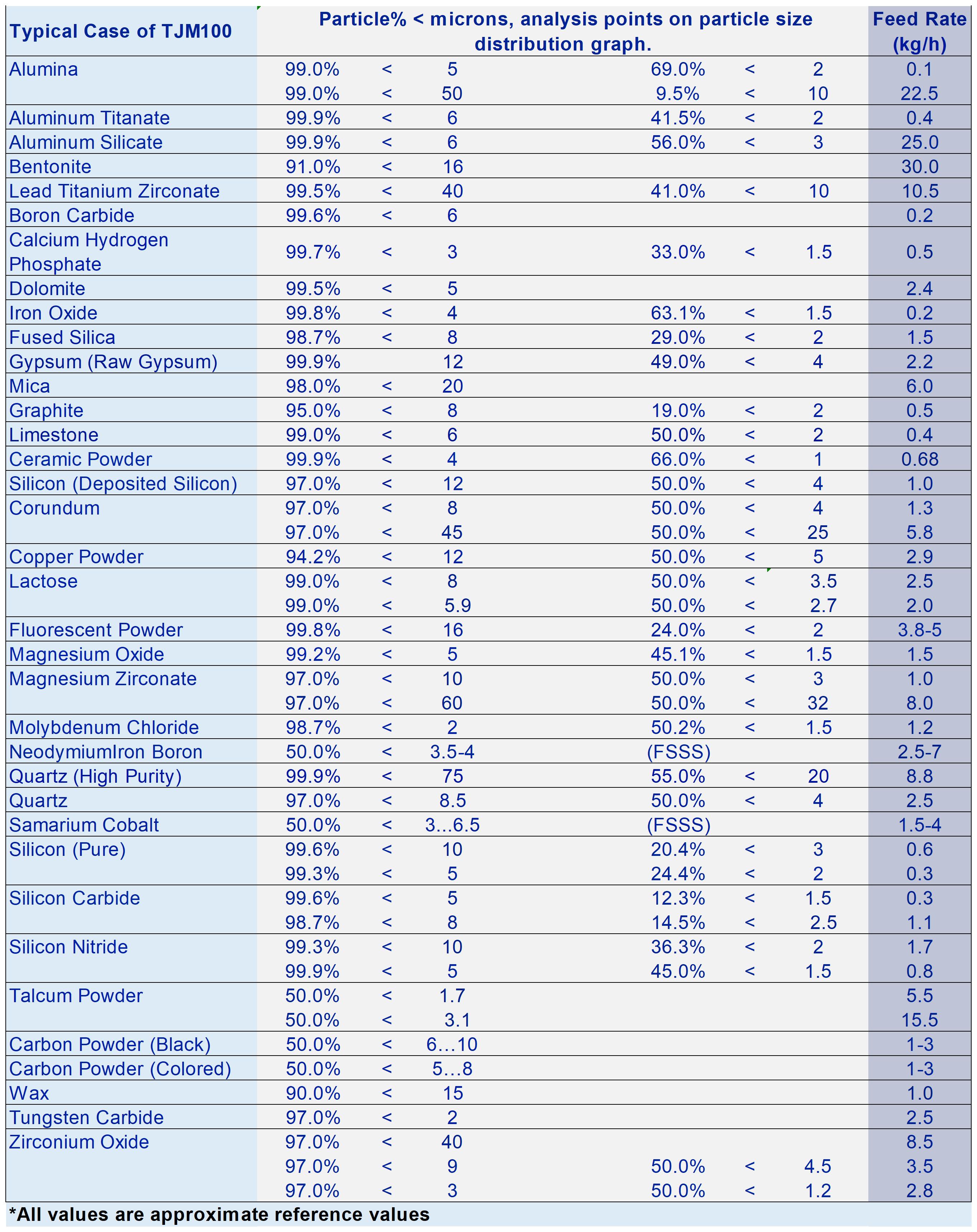

Fluidized Bed Air Jet Mill consists of a classifier wheel chamber and a fluidized bed air jet milling chamber, where the number of nozzles is determined by the size of the grinder. Material particles entering the injection device will be accelerated and then collide with each other upon reaching the intersection of the injection air. When the air reaches the edge of the injector, it forms a shearing airflow, at which point the material particles will collide with each other at the intersection of the airflow, ultimately shattering. Because the materials are mutually ground, contamination of the materials can be avoided. The ground materials will pass through the classifier wheel and be discharged into the separator system (cyclone separator or dust filter). Adjusting the airflow rate, grinding air pressure, and classifier wheel speed can adjust the cutting particle size. Achievable particle size D97 ranges from 2 μm to 60 μm, and D50 ranges from 0.6 to 45 μm.

Ultrafine Powder Applications

TungKuLa has rich experience and a good track record in the production and sale of jet mill systems.

Name: Joye

Mobile:+86 166 2114 0018

Tel:+86 166 2114 0018

Whatsapp:+86 166 2114 0018

Email:info@tungkula.net

Add:Warehouse 3, No.1537, Airport Fourth Road, Xihanggang Economic Development Zone, Shuangliu District, Chengdu, Sichuan Province, China