Home Products Air Jet Sieve & Lab Units Wet Sieve WS-X

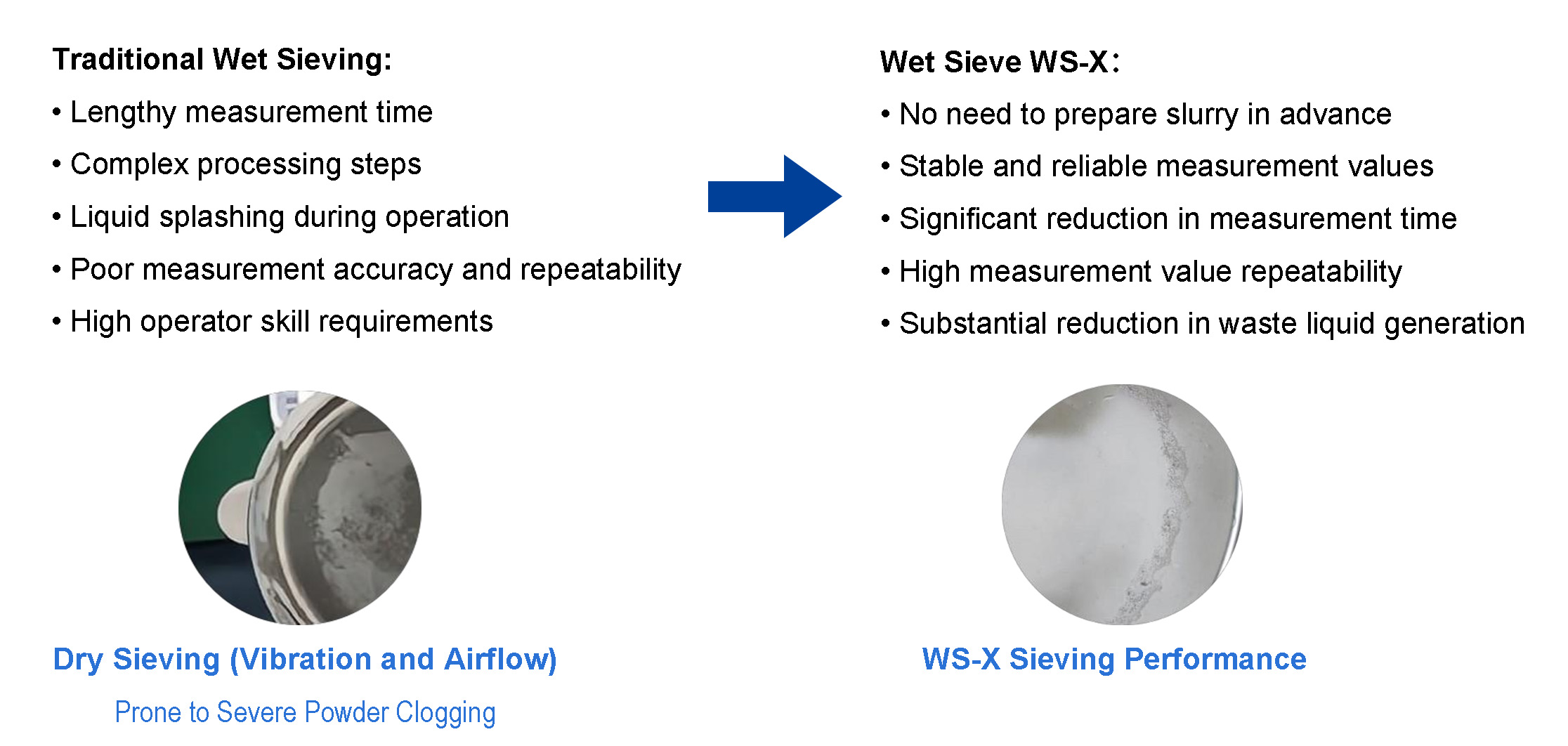

Tungkula Wet Sieve WS-X: Designed specifically for dealing with agglomerated powder sieving.

Method 1:

Before introducing water initially, smaller particles are separated from the dry powder. This promotes faster saturation of other particles after water introduction, facilitating more effective sieving. Material saturated through rotary spraying in the sieve mesh is encouraged to flow out due to high-frequency vibration.

Method 2:

The spraying solution is introduced first, allowing it to thoroughly combine with the material particles, accelerating particle saturation. Vibration is then initiated, promoting gravitational flow with high-frequency vibration.

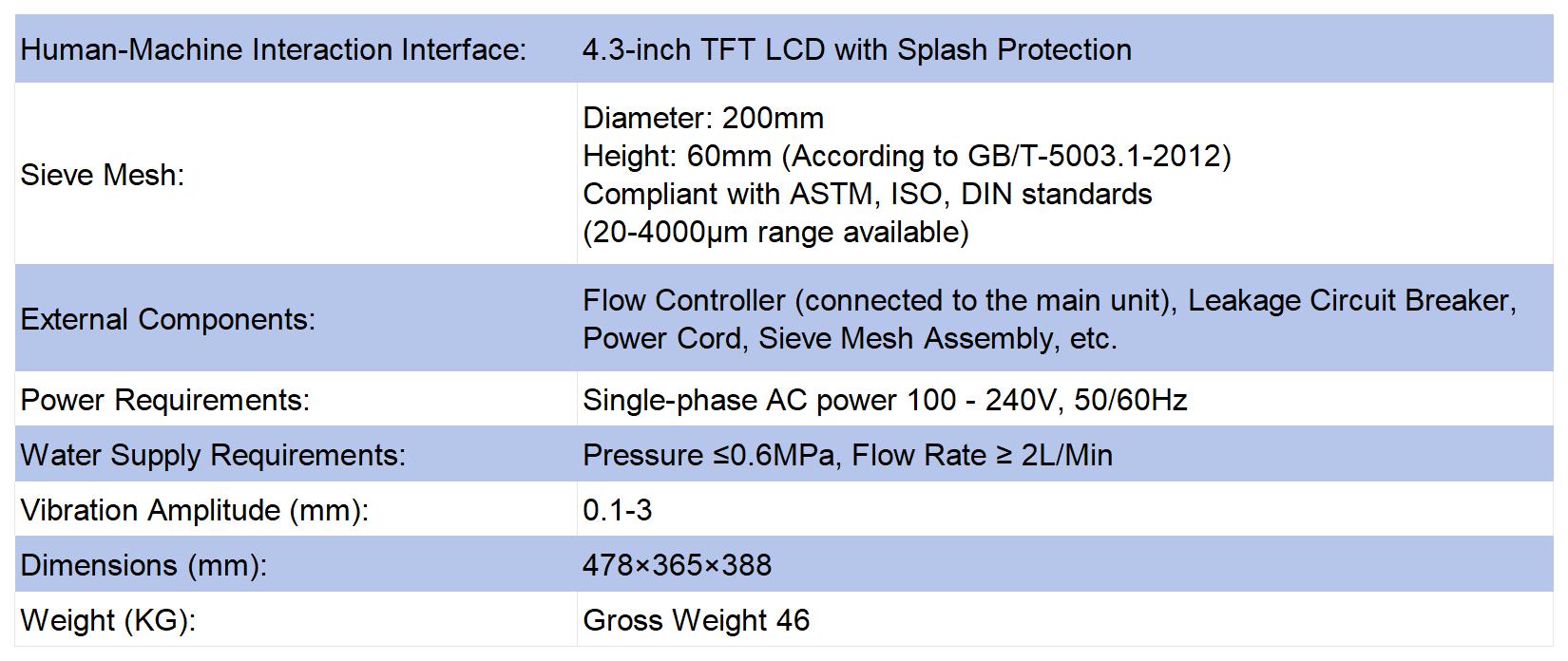

◆ 4.3-inch smart display screen for convenient parameter adjustments and easy operation.

◆ Dual-position rotary spraying system with servo control for quick adjustment of nozzle rotation speed.

◆ Optional sequencing of vibration before spraying or spraying before vibration.

◆ Vibration control for adjusting amplitude and frequency.

◆ Proportional valve for regulating flow rate to accommodate various materials.◆ Equipped with leakage protection to ensure safe and stable equipment operation.

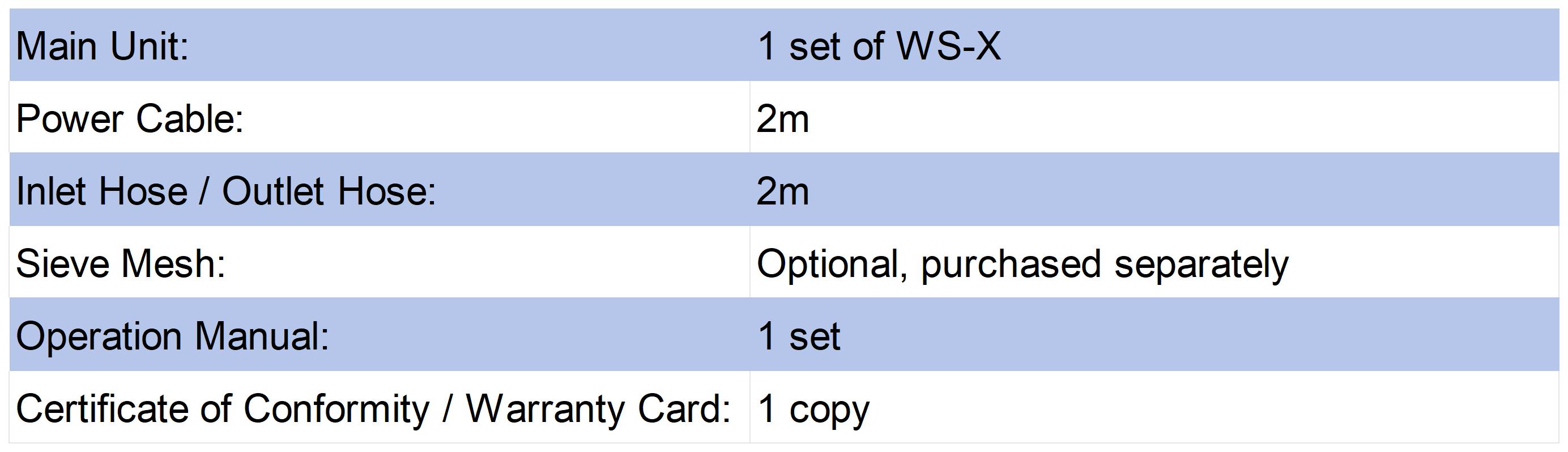

For specific details, please feel free to contact us.

Name: Joye

Mobile:+86 166 2114 0018

Tel:+86 166 2114 0018

Whatsapp:+86 166 2114 0018

Email:info@tungkula.net

Add:Warehouse 3, No.1537, Airport Fourth Road, Xihanggang Economic Development Zone, Shuangliu District, Chengdu, Sichuan Province, China