Home Products Air Jet Sieve & Lab Units Laboratory-Scale Particle Modification C

In the surface coating and modification process of ultrafine minerals and metallic powders (such as calcium carbonate, talc powder, quartz powder, barite, alumina, aluminum hydroxide, silver powder, precipitated silica, titanium dioxide, and other materials), T-MIX has been proven to be a super successful equipment.

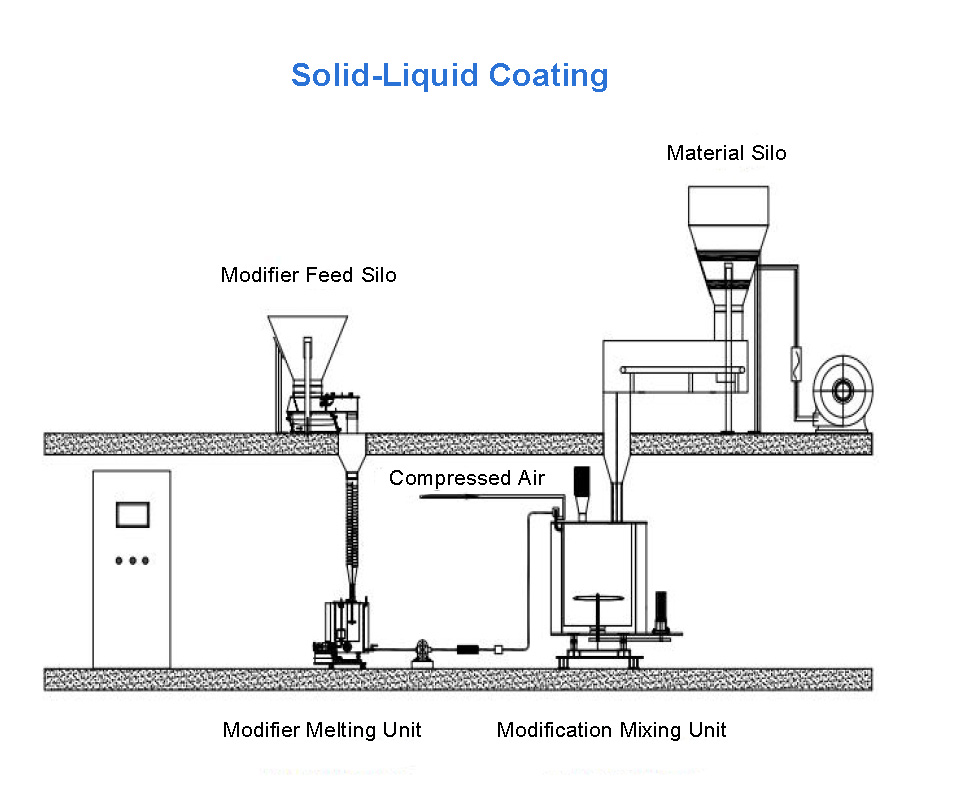

Modifying agents like stearic acid or silane coupling agents are often used to process and coat dry powder materials. Depending on the nature and fineness of different mineral powders, the dosage of coating modifier typically ranges from about 0.4% to 1.5%. Tungkula's coating and modification system, based on its unique professional expertise and technological experience, has invented and refined this technology solution. This unique modification and technology includes not only comprehensive feedback control and regulation technology but also the supply of stearic acid, spraying techniques and an air circulation system within a closed pipeline.

The actual modification and coating process takes place in the T-MIX, achieving the effect of highly efficient mixing and coating. The final product is a highly desirable material with uniformly coated surfaces. The size of the coated particles remains consistent with the feed material.

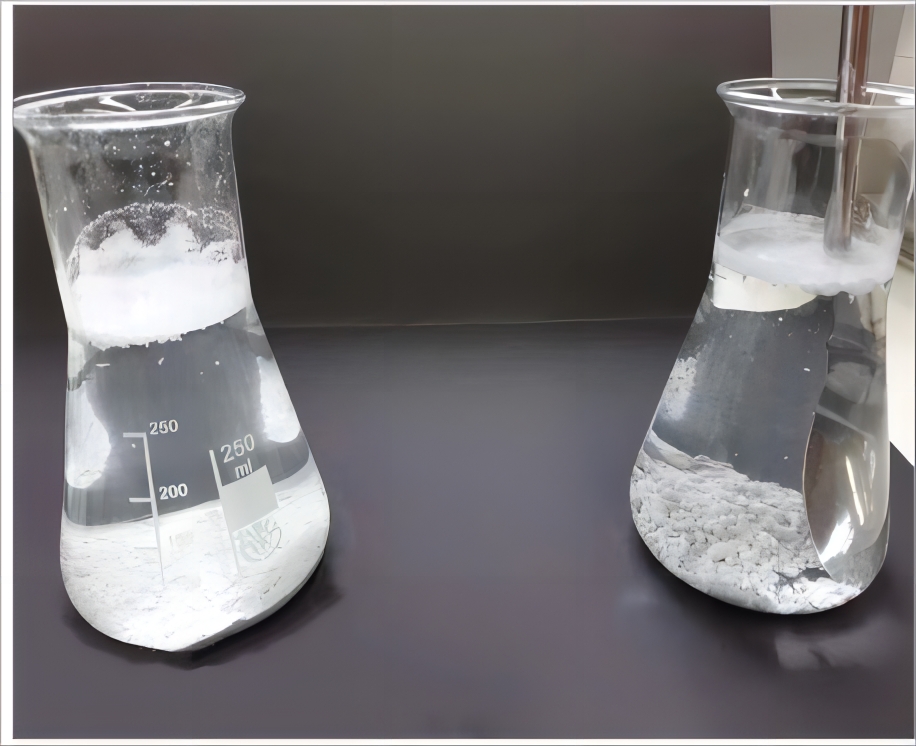

The above image shows calcium carbonateafter coating and modification. Using the WATER GLASS TEST experiment, it's evident that the water is entirely clear. The powder remains in the water for an extended period without any emulsification or suspension.

The above image depicts coated and modified alumina. Alumina, being a high-hardness material, cannot be effectively modified through traditional mechanical grinding. This process can result in significant contamination. T-MIX perfectly addresses this issue. After shaking the modified alumina in water, as seen in the image, the water remains exceptionally clear.

The image showcases coated and modified calcium oxide. Poorly modified calcium oxide would produce calcium hydroxide when placed in water. However, well-modified calcium oxide doesn't react and the water remains clear.

Optional configurations:

wear-resistant lining, wear-resistant mixing paddles, high-performance paddles, injection nozzles, negative pressure unit, heating unit, observation window.

For specific details, please feel free to contact us.

Name: Joye

Mobile:+86 166 2114 0018

Tel:+86 166 2114 0018

Whatsapp:+86 166 2114 0018

Email:info@tungkula.net

Add:Warehouse 3, No.1537, Airport Fourth Road, Xihanggang Economic Development Zone, Shuangliu District, Chengdu, Sichuan Province, China