Home Products Modification Coating Particle Surface Modification Coating Ma

In the surface coating and modification process of ultrafine minerals and metallic powders (such as calcium carbonate powder, talc powder, quartz powder, barite, alumina, aluminum hydroxide, silver powder, precipitated silica, titanium dioxide, graphite, and other materials), mechanical stirring has been proven to be a highly successful equipment.

For multiple particle coating scenarios, it can be upgraded to the top configuration (screening + dispersion), increasing the coating rate to over 99% while reducing the usage of modifiers to as low as 0.4%.

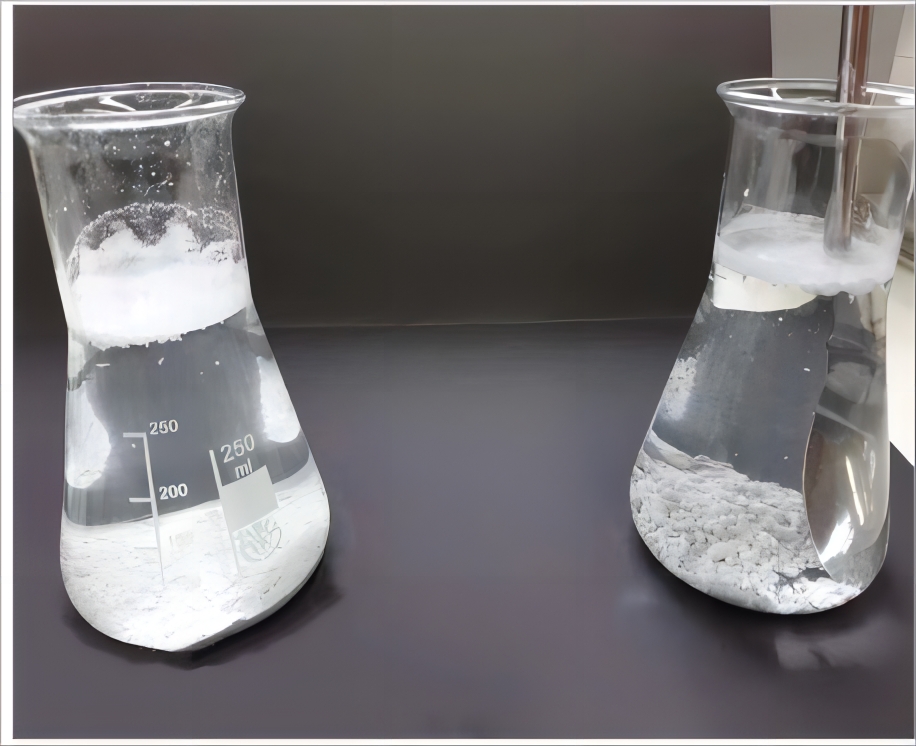

The above image shows calcium carbonateafter coating and modification. Using the WATER GLASS TEST experiment, it's evident that the water is entirely clear. The powder remains in the water for an extended period without any emulsification or suspension.

The above image depicts coated and modified alumina. Alumina, being a high-hardness material, cannot be effectively modified through traditional mechanical grinding. This process can result in significant contamination. T-MIX perfectly addresses this issue. After shaking the modified alumina in water, as seen in the image, the water remains exceptionally clear.

The image showcases coated and modified calcium oxide. Poorly modified calcium oxide would produce calcium hydroxide when placed in water. However, well-modified calcium oxide doesn't react and the water remains clear.

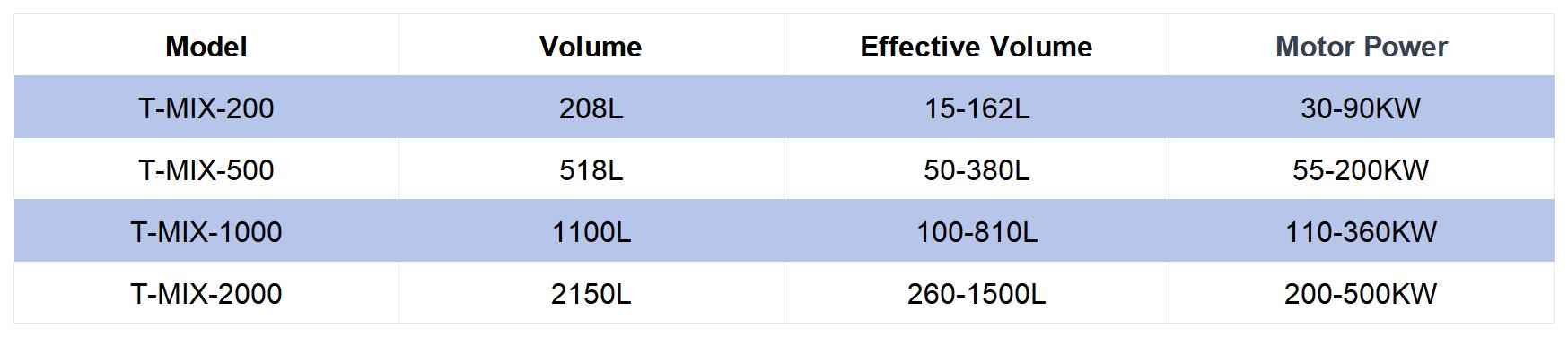

In many cases, materials are becoming increasingly expensive and time-consuming to prepare. For instance, nanometer particles, electronic materials, and specialty chemical materials are all experiencing this trend. Researchers often have limited quantities of materials for research and development. However, during the research and development phase, testing of a large number of materials with similar properties is necessary, which intensifies the demand for different scale coating equipment.

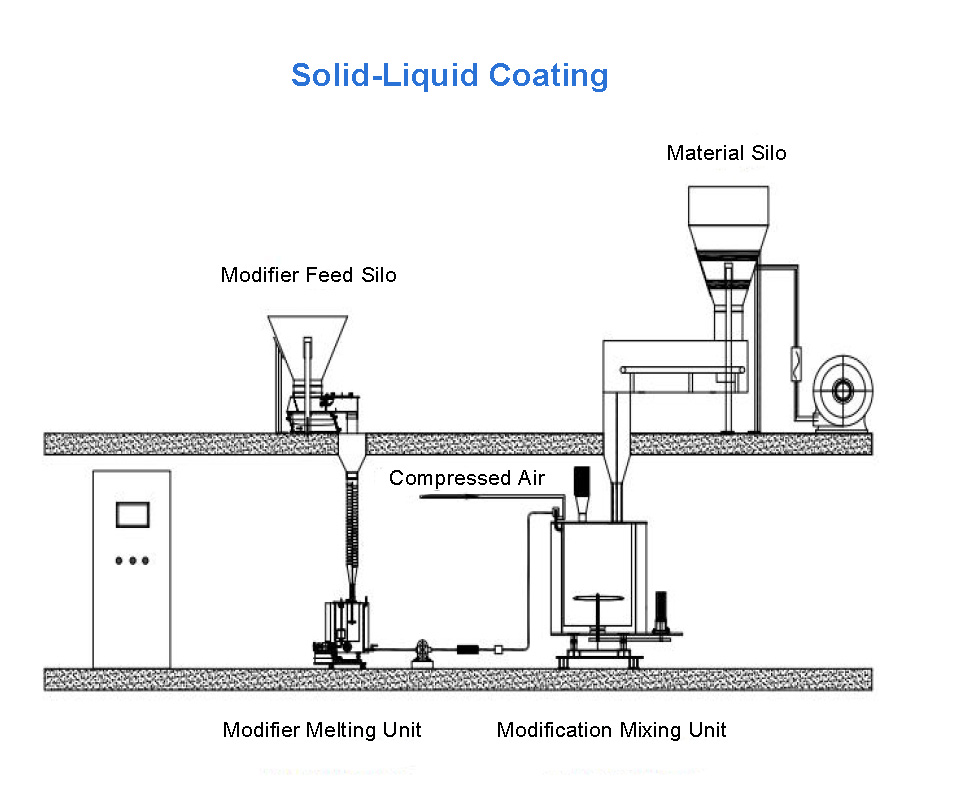

Tungkula's T-MIX production model offers the most suitable solution for customers, ranging from standalone equipment to complete production line assembly. Inside the chamber, in addition to the traditional baffle plates, a dual-drive impeller system is also installed to create a better chaotic effect on the internal materials, achieving the best uniform coating.

The PLC system enables fully automated operation with professional configuration design and a user-friendly interface that responds with just a touch. Whether it is material parameters such as feeding speed, weight changes, liquid temperature, gas temperature, material level changes, humidity, or inherent parameters such as motor speed and motor vibration, all these key parameter points are controlled in a fully closed loop. In conjunction with our advanced process solutions, they will provide customers with satisfactory surface coating solutions for powdered materials.

T-MIX Batch-Processing model boasts a more extensive range of functions, not only with improved upgrades at the discharge end but also with patented designs added inside the chamber, further enhancing the mixing and coating effects and facilitating the unloading and collection of materials.

For smaller scale coating equipments, please click here:

Laboratory-Scale Modification Coating Machine T-MIX

For specific details, feel free to contact us.

Name: Joye

Mobile:+86 166 2114 0018

Tel:+86 166 2114 0018

Whatsapp:+86 166 2114 0018

Email:info@tungkula.net

Add:Warehouse 3, No.1537, Airport Fourth Road, Xihanggang Economic Development Zone, Shuangliu District, Chengdu, Sichuan Province, China